Newmont Mining had a Public outreach this past Wednesday at the local community building in Wendover. Newmont representatives were there, informally explaining the different phases of the mining process, and also the impact, or none impact on the environment.

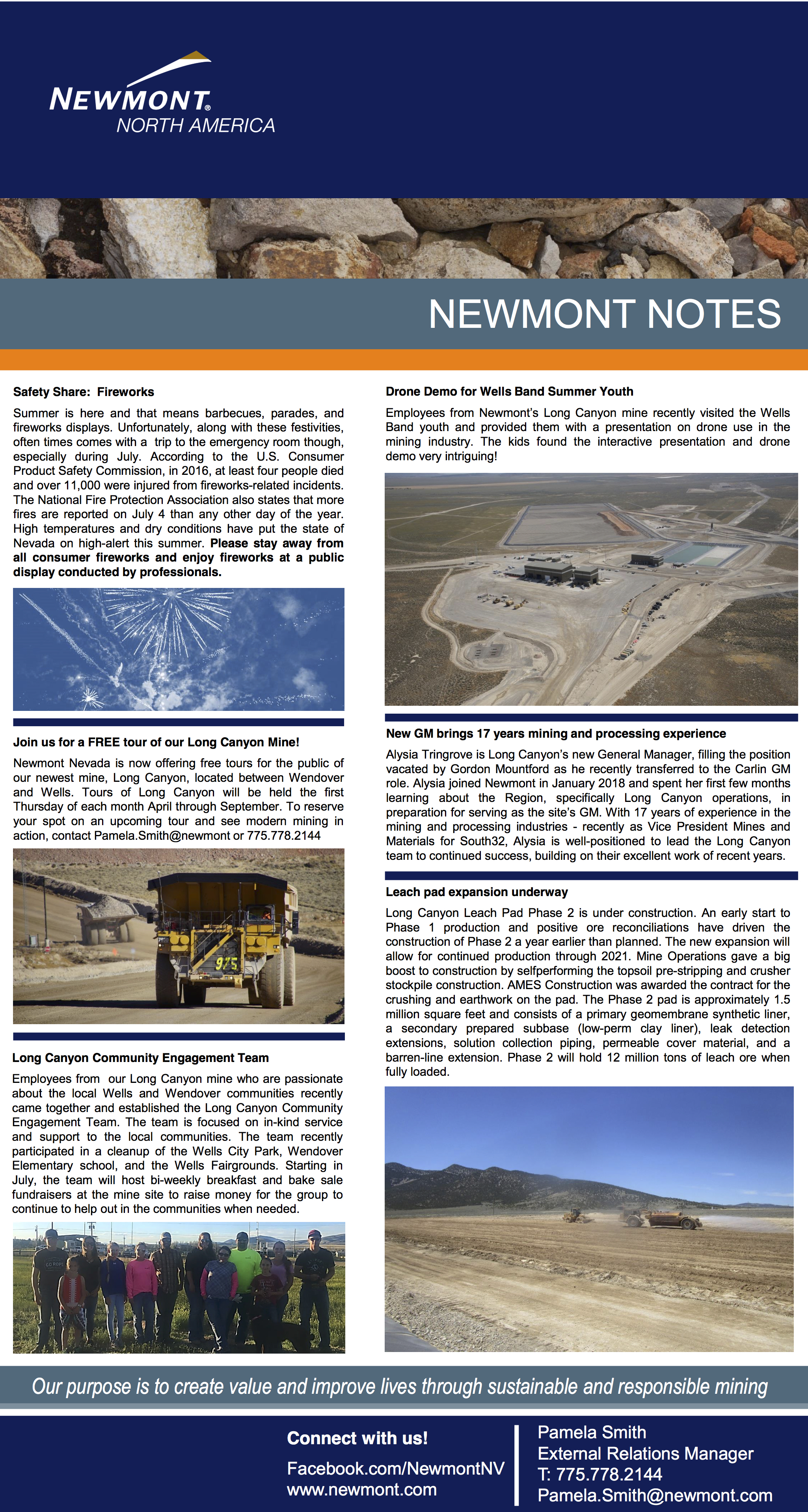

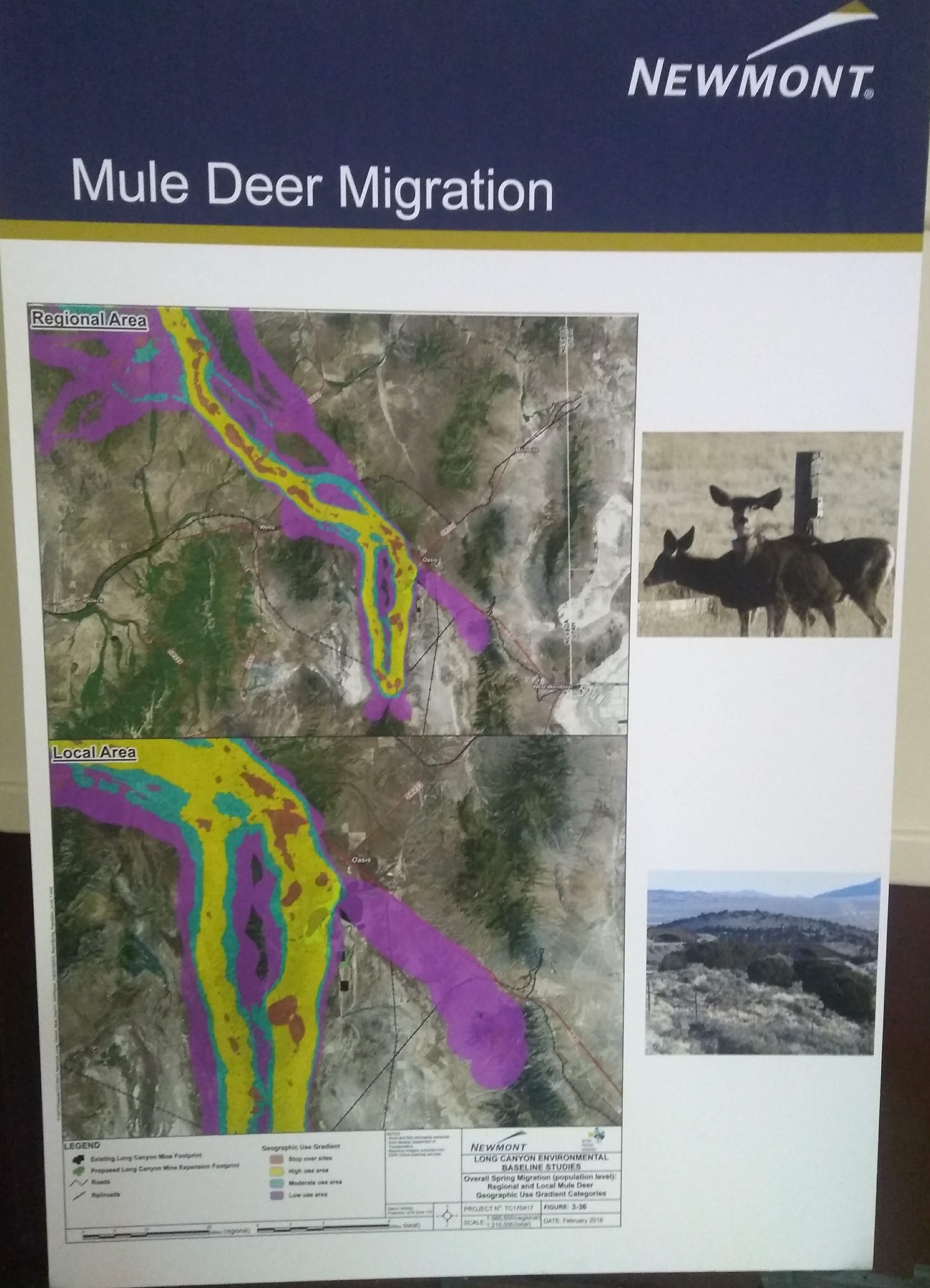

One panel, explained by Steve Grosz, showed the migration of deer near Long Canyon gold mine, near Oasis. If you are new to the area, Oasis is about half way between Wells and Wendover, on I-80. The graph showed that the deer were still using the same route as in the past, a finding and observation from the Department of Wild Life. The conclusion is that the mine had a minimal effect on the deer migration. Newmont also help finance the pricey collars put upon some of the deers for the research. Stephanie Douglas explains to some local residents, how the Johnson Spring wetland and the wild life within are monitored by Newmont.

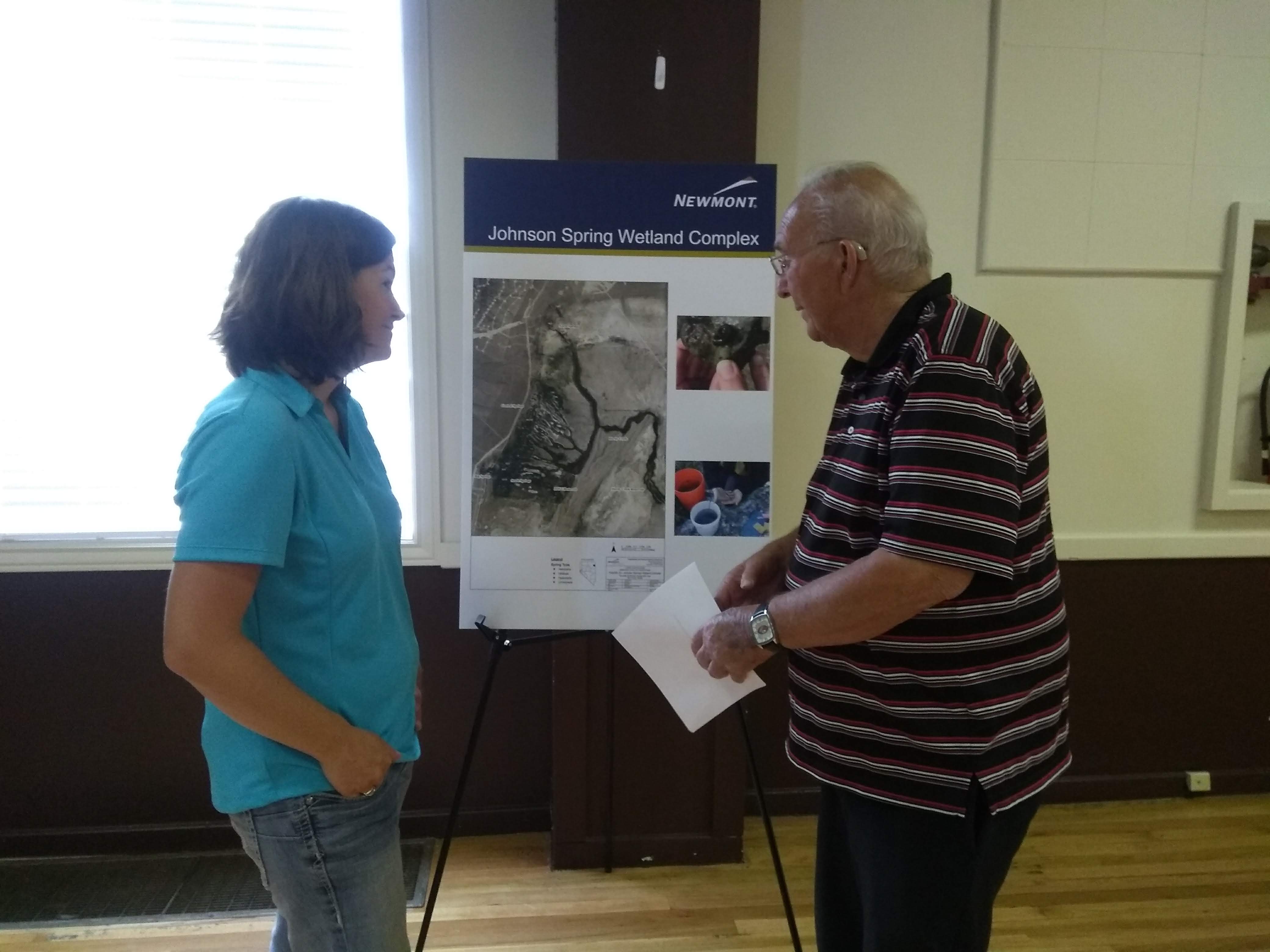

At a different station, Mark Brazier and Randy Walund explain the process of dewatering. Geologists also use drilling and sampling data to identify wet areas. Water can cause major problems in both open pit and underground mines. If areas of high water content can be avoided or planned for in advance, we can reduce safety risks, costs and production interruptions.

Yet at an other station, Production geologists use information they obtain from sampling, testing, mapping and observation to determine the most efficient and effective mining techniques, as well as to identify the grade (amount of mineral) in the ore. In gold and silver mining, grade is reported as grams per ton. Copper grade is reported as a percentage. It is important to know the grade to determine which rock is sent to the plant for processing and which rock is sent to the waste rock storage area.

By using this data and complex computer programs to more accurately define the orebody, mine engineers can determine mining methods, design blast patterns, design dig patterns, and maximize the safety and efficiency of production – as well as determine how the ore should be processed.

Everything was quiet interesting, and all questions well answered by everybody at Newmont.